Published: 2023-12-03 10:47:32

Published: 2023-12-03 10:47:32

Views: 571

Views: 571

admin

admin

First, material common ground:

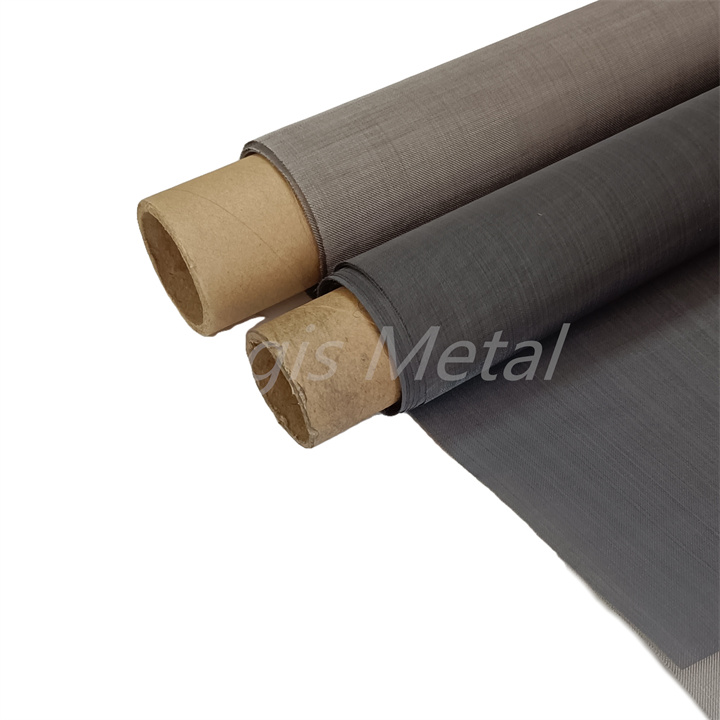

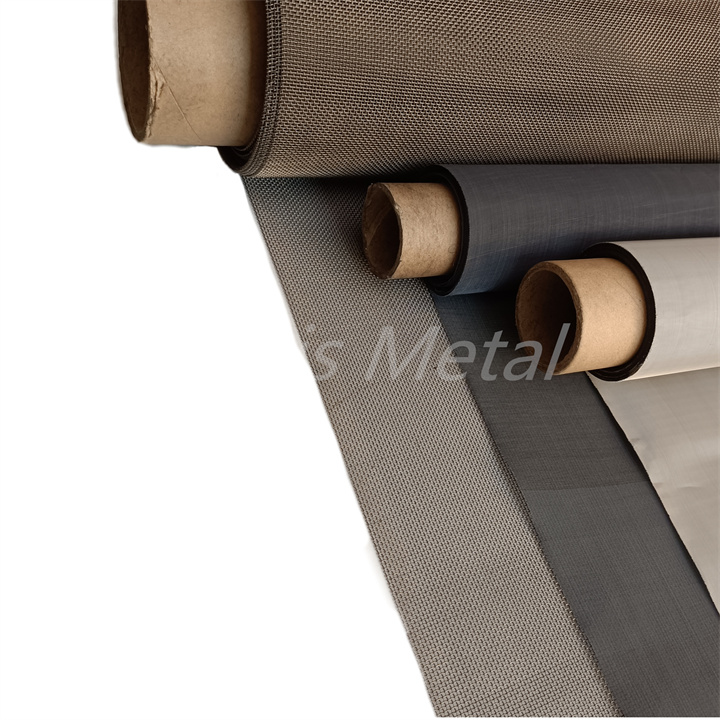

White titanium mesh and black titanium mesh are produced by pure titanium wire, pure titanium wire material grade is usually used TA1, which has the advantages of high elongation, high titanium content, high mechanical strength and easy processing.

Second, common process

The processing method and the machinery are exactly the same – all of them are plain square hole braided, from the raw material wire diameter, material, elongation, tensile strength testing methods and testing instruments are consistent. All of them are made of shuttleless woven mesh. Warping knitting, mesh leveling, laser cutting processes are the same.

Third, packaging common ground

The same packaging is adopted: the inner packaging is waterproof with bubble pad, and the outer packaging is laminated wooden box, which is anti-extrusion and collision.

Four, the only difference

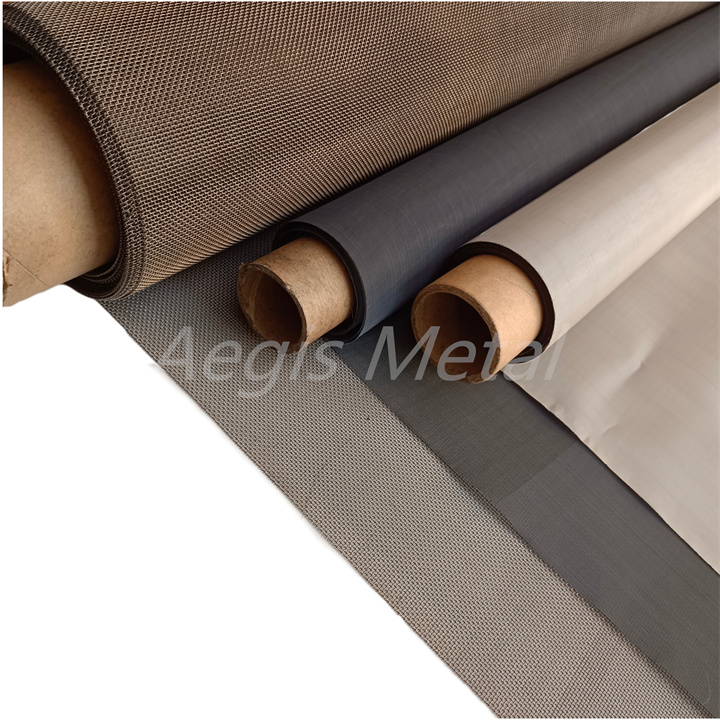

The only difference is the surface: the white surface is free of any impurities, and the black surface has a brushed graphite milk.

Five .Use

White titanium mesh surface does not contain any impurities suitable for ion membrane electrolytic cell titanium mesh anode, anodic oxidation experiment, catalyst carrier mesh, pure chemical liquid filter and other can not be polluted solution filtration.

The surface of the black titanium mesh contains brushed graphite emulsion coating, which is suitable for seawater desalination titanium filter and chemical filtration. The surface coating can slow down the erosion received by the titanium substrate and extend the service life.

Hot News

Hot News