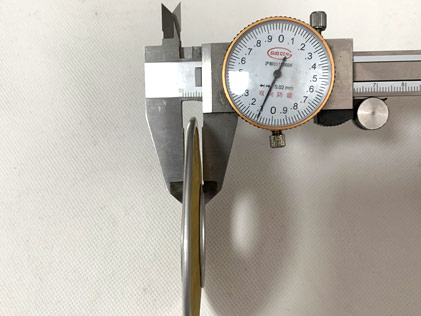

Wire Raw Material Testing

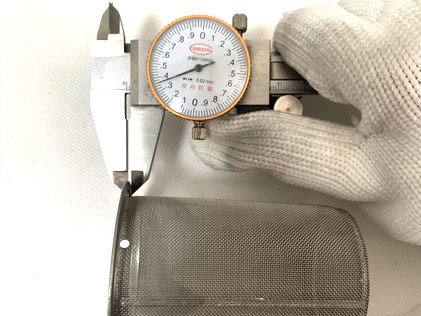

Wire Thickness Testing

Wire Tensile Trength Testing

Finished Mesh Material Testing

Mesh Thickness Testing

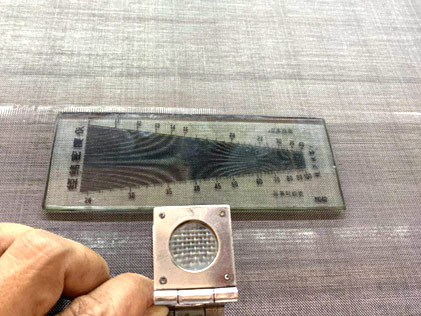

Mesh Count Testing

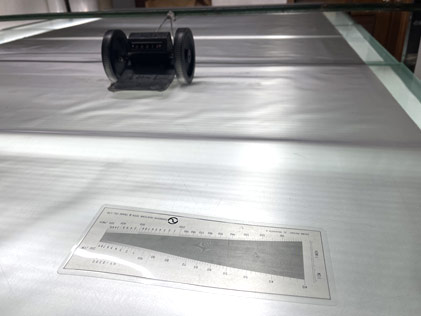

Mesh Surface Testing

Mesh Roll Measuring

Mesh Length Measurement

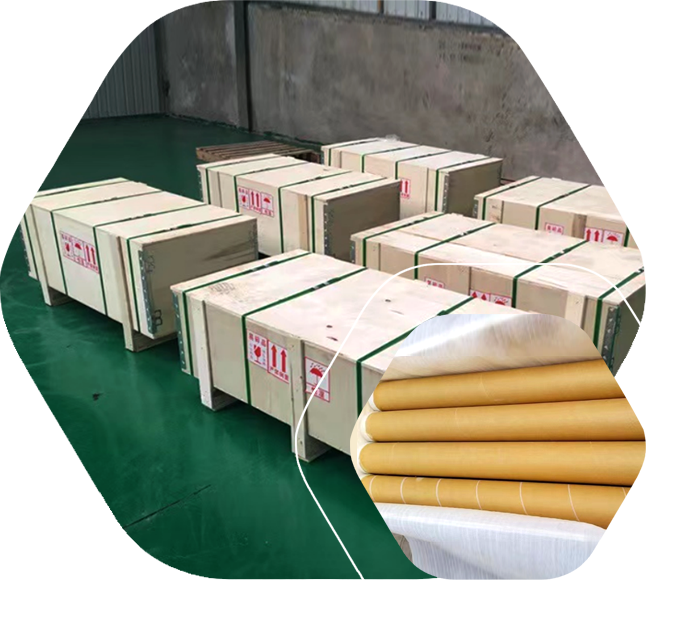

Mesh Packing

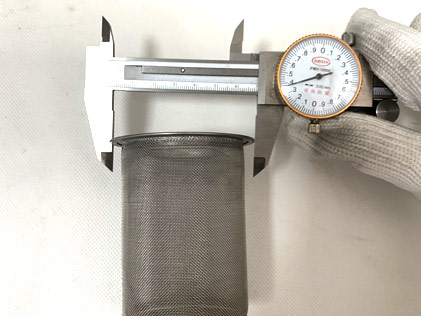

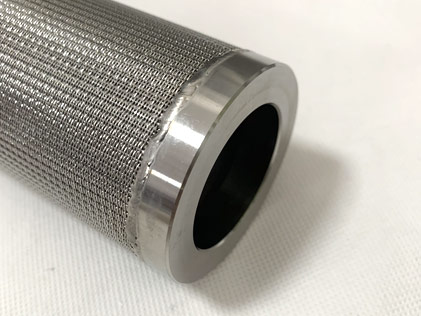

filter tube

Inner Diameter

Outter Diameter

Thickness for Flange

Diameter for Bottom

Height

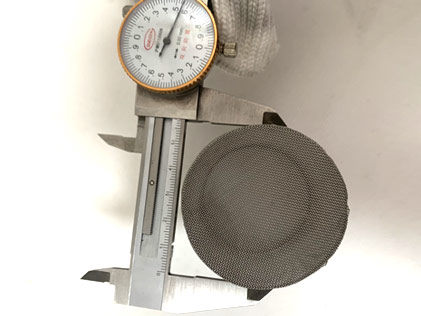

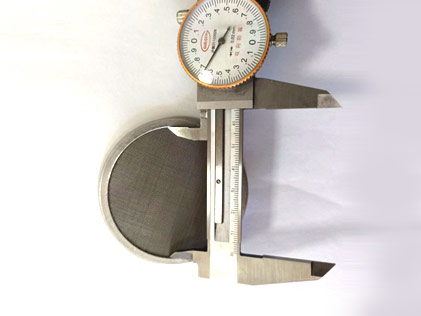

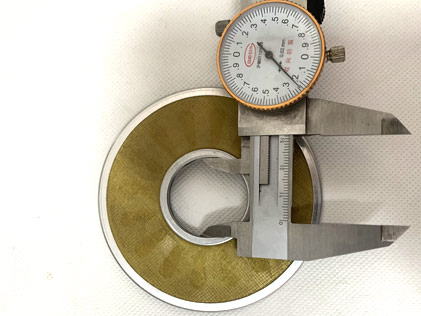

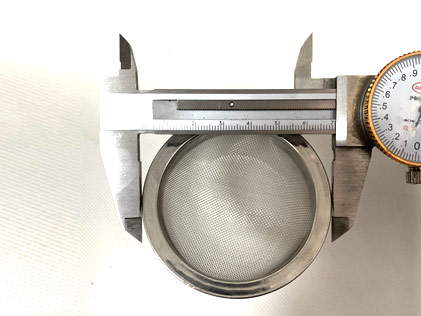

Filter disc

Thickness

Inner diameter

Outter diameter

Outter diameter

Inner diameter

Thickness

Filter cap

Outter diameter

Inner diameter

Thickness for flange

Height

As for the metal filter cartridges, such as pleated, sintered mesh, sintered powder porous filter types, any type of the Threads or Fitting can be made as per your drawing or request.

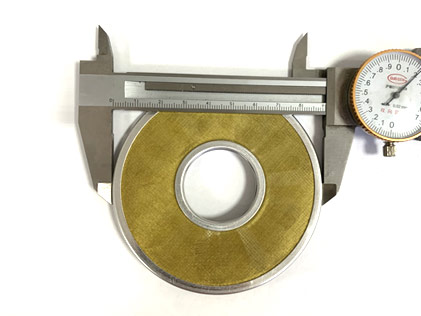

Flange

M20

Plane/DOE

M30

222

Triangle