Published: 2023-12-28 09:09:29

Published: 2023-12-28 09:09:29

Views: 643

Views: 643

admin

admin

Nickel wire mesh is woven by nickel wire filter, the main common nickel wire is N4 and N6, N6 material mainly contains nickel content of more than 99.5%, applied to N4 material nickel wire mesh can be replaced by N6 material nickel wire mesh.

Nickel wire mesh has strong corrosion resistance, acid and alkali resistance, mainly used in strong acid, alkali environmental conditions of screening and gas, liquid filtration and other media separation.

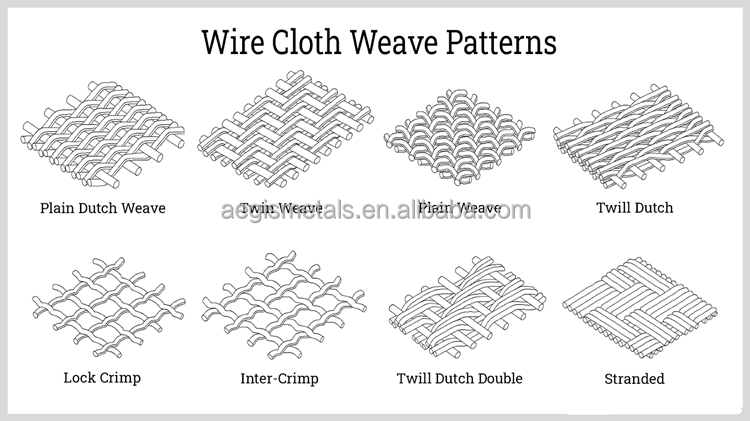

The main weaving processes of nickel wire mesh are plain weaving, twill weaving and mat weaving.

Plain weave main specifications for 1-200 mesh, plain weave process is characterized by the same density of warp and weft wire per inch.

The main specification of twill weave is 1-220 mesh, the tension of twill weave is better than plain weave weave, the main specification of mat weave is 45-800 mesh, the minimum filtration accuracy can reach 20um, which is the filtration accuracy that plain weave weave and twill weave weave net can not achieve.

Nickel wire mesh production can be produced according to customer needs and customer requirements for wire diameter and mesh.

Pure nickel filter is mainly used in petroleum, chemical, aerospace and other industries.

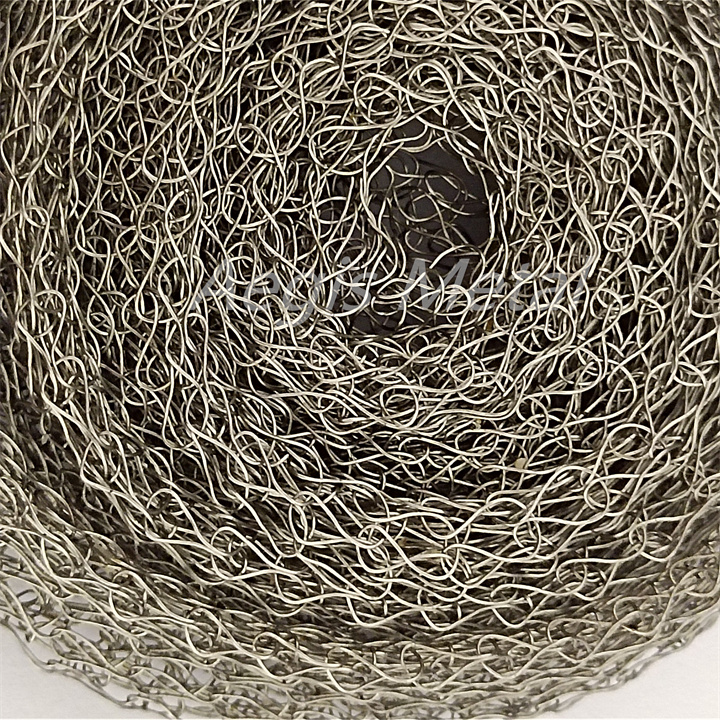

Nickel knitted wire mesh:

nickel wire mesh is also a kind of nickel wire mesh, it is a pure nickel wire vapor liquid filter, also known as pure nickel wire foam mesh, pure nickel wire foam net.

Pure nickel wire knitting wire mesh is a special croquet knitting process prepared into the wire mesh, widely used in special production environment of wire mesh defoam, oil and gas processors, internal combustion engine filter, dust filter, etc., the general specification of the net width of 25mm-600mm. Mesh size, filtration accuracy can be produced according to customer requirements

——————————————————————————————————————————————————————-

My WhatsApp: +86 13313083930

My email address : ruby@aegismetals.net

For more product pictures and videos, please contact me via WhatsApp or email

Hot News

Hot News