Published: 2024-01-03 02:47:53

Published: 2024-01-03 02:47:53

Views: 593

Views: 593

admin

admin

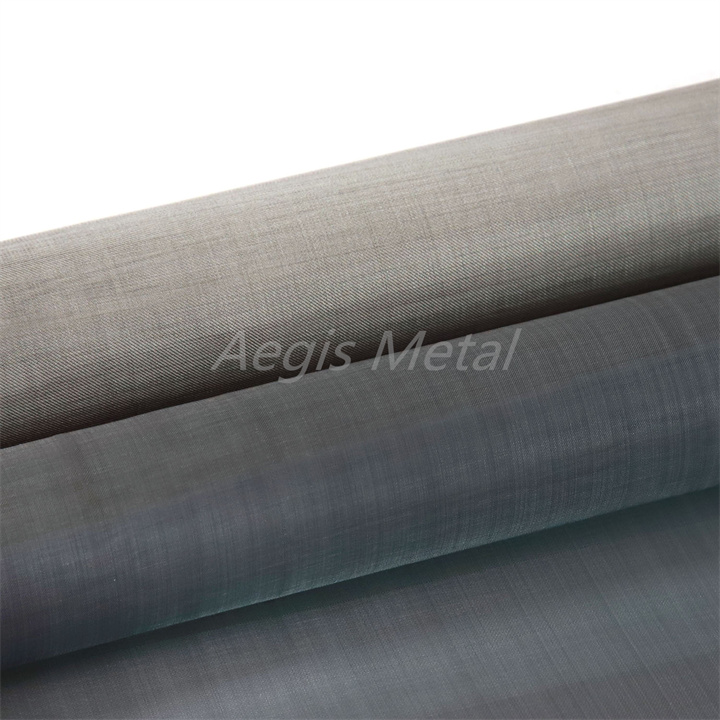

Black molybdenum and bright molybdenum

My WhatsApp: +86 13313083930

My email address : ruby@aegismetals.net

For more product pictures and videos, please contact me via WhatsApp or email

Hot News

Hot News