Published: 2024-03-08 03:35:42

Published: 2024-03-08 03:35:42

Views: 606

Views: 606

admin

admin

Chemical compositions near the grain boundaries of inconel steel products can be altered by precipitationof chromium-rich particles. The resulting chromium-poor zone at the grain boundary makes 4cr13 stainless steel tube products vulnerable to intergranular anode attack, even under stress-free conditions.

The designation of inconel steel products means that 12% Cr content is more than a little. Most of the stainless steel is based on the Fe-Cr-C Fe-Cr-Ni-C system, but is also very important for other alloying elements.

inconel steel products can exist in several crystal forms, the most common of which are body-centered cubic (bcc) and face-centered cubic (fcc). In pure iron, the fcc structure still exists between 910 and 1400 ° C, and this time interval below and above the body-centered cubic structure reaches a melting temperature of up to 1539 ° C.

The importance of the metallurgical transformation of inconel steel products at this stage cannot be overestimated. This conversion allows a wide range of microstructure to be achieved through controlled heat treatment. Essentially with microstructure, mechanical properties, inconel steel products can therefore be obtained in a very large range of strength, toughness, etc. The conventional production of inconel steel 100 mpa over 1 GPA has a strong competitive strength. Therefore, the primary concern is knowledge of the relative stability of the bcc and fcc structures of iron inconel steels.

My WhatsApp: +86 13313083930

My email address : ruby@aegismetals.net

For more product pictures and videos, please contact me via WhatsApp or email

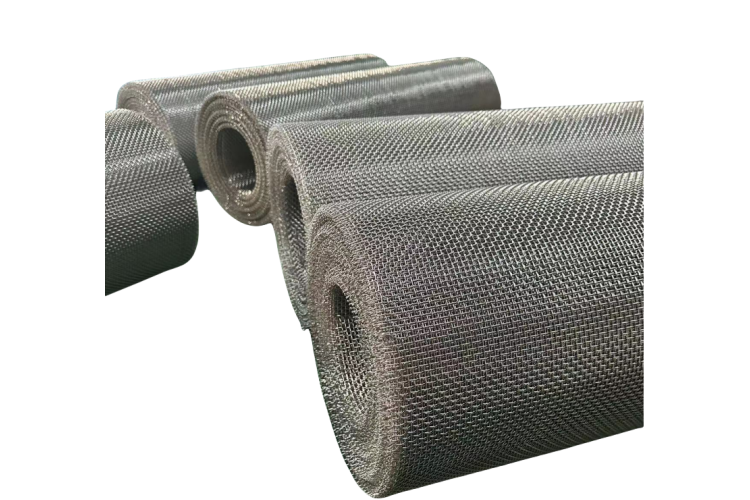

inconel alloy mesh product

Hot News

Hot News