Published: 2024-04-15 02:51:16

Published: 2024-04-15 02:51:16

Views: 762

Views: 762

admin

admin

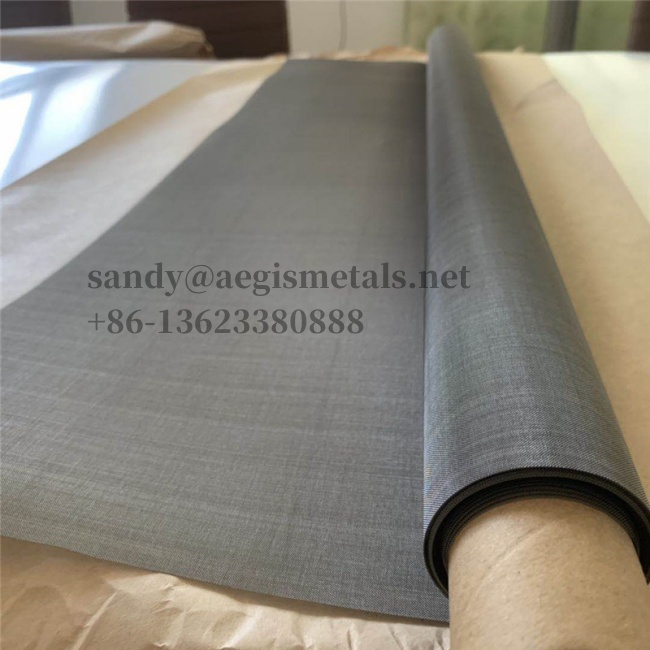

AGS 24mesh 0.35mmx 0.709mm Square Hole Molybdenum mesh/molybdenum wire mesh/molybdenum filter mesh

Molybdenum mesh (molybdenum wire mesh, high temperature resistant molybdenum mesh, strong corrosion resistant molybdenum mesh, molybdenum grid mesh, etc.)

-Implementation standards: molybdenum wire meets national standards or American standards

-Purity: ≥99.95% or higher purity, and the surface of the product has uniform mesh, no broken wires, and no loopholes.]

-Surface: black, alkali cleaning, electrolytic polishing

-Hole type: square hole

-Weaving method: plain weave, twill weave, mat weave, edge wrapping, etc.

-Mesh number: 0.5 mesh to 400 mesh,

-Aperture: 0.02-23.4mm,

-Width: 50mm-2000mm.

–Plain weave molybdenum wire mesh:

Each warp wire passes above and below each weft wire crosswise. The two wires are the same size, and the warp and weft are 90°.

The net woven in this way is square and the mesh size is uniform.

–Twill weave molybdenum wire mesh:

Each warp thread crosses above and below every two weft threads, and each weft thread crosses above and below every two warp threads.

–Dutch weave molybdenum wire mesh:

The warp and weft yarns have different diameters and mesh numbers. They are characterized by sparse warp and dense weft, thick warp and thin weft. The mat type can also be made into plain weave and twill weave.

–Edges Wrapping molybdenum wire mesh:

The two adjacent warp threads at both ends of the edge-wrapped wire mesh are connected, while the warp threads without edge wrapping are not connected. Our company can perform edge wrapping according to customer requirements.

Molybdenum mesh features: High strength, high temperature resistance, corrosion resistance and wear resistance

Molybdenum mesh application: Widely used in vacuum sintering furnaces and infiltration heat treatment furnaces.

More info, please contact us our team: sandy@aegismetals.net +86-13623380888

Hot News

Hot News