Published: 2025-04-18 04:09:14

Published: 2025-04-18 04:09:14

Views: 21

Views: 21

admin

admin

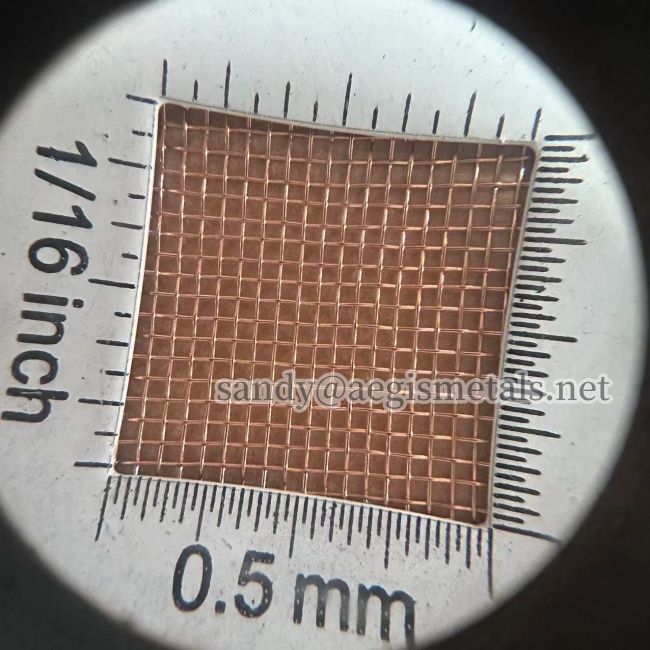

Plain weave 350 mesh C1220 copper mesh is a copper mesh made of C1220 phosphorus deoxidized copper using plain weave technology, with 350 mesh holes within one inch length.

(1)Material Characteristics : C1220 copper contains a small amount of phosphorus, generally ranging from 0.015% to 0.04%, with the remaining main component being copper. This copper material has good strength, corrosion resistance, and moderate conductivity. Compared with pure copper, it has relatively high strength and hardness, slightly better corrosion resistance, and still excellent electrical and thermal conductivity, which can meet various practical application needs.

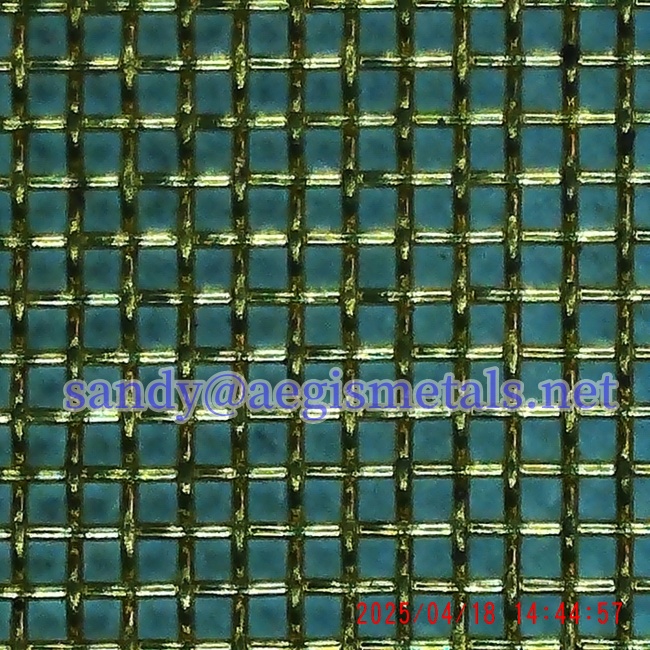

(2)Weaving process : Adopting plain weave, that is, each warp and weft are interwoven vertically with each other, forming a square mesh. This weaving method makes the copper mesh structure compact, with a smooth surface, good stability and uniformity, able to withstand certain pressure and tension, and not easily deformed.

(3)Mesh specification : 350 mesh indicates a mesh count of 350 per inch length. The higher the mesh size, the smaller the mesh size, and the higher the filtration accuracy. It can screen or filter finer particles, powders, and other substances, and also provide a finer shielding effect.

(4)Product Usage: Due to its fine mesh and excellent physical and chemical properties, plain weave 350 mesh C1220 copper mesh can be used for precision filtration in industries such as chemical, food, and pharmaceutical, effectively intercepting small impurity particles; In electronic devices, it can be used for electromagnetic shielding to prevent electromagnetic interference and radiation; It can also be used in situations that require high-precision screening, such as screening fine powder materials, precious metal powders, etc.

(5)Appearance features: The surface is smooth and flat, with uniform and consistent mesh holes, presenting the metallic luster of the copper material itself. Due to the characteristics of weaving techniques, the pattern formed by interweaving warp and weft threads is neat and regular, with a certain degree of aesthetic appeal.

(6)Processing difficulty : Due to the relatively high strength and hardness of C1220 copper, there are high requirements for the process and equipment during the weaving process. More precise control and appropriate processing parameters are needed to ensure the uniformity of the mesh and the overall quality of the copper mesh.

(7)Product cost : Producing C1220 copper requires adding phosphorus to pure copper for deoxidation treatment, which is a complex production process. In addition, plain weave 350 mesh belongs to a higher mesh number, requiring high production equipment and technical requirements, so its cost is relatively high.

Hot News

Hot News