| Property | Details |

| Chemical Composition | 70% Copper(Cu),30% Nickel(Ni) |

| lron (Fe) | Less than 0.5%(trace amounts) |

| Manganese(Mn) | Up to 1% (sometimes added for corrosion resistance) |

| Silicon(Si) | Up to 0.5% |

| Tensile Strength | 450 MPa to600 MPa |

| Yield Strength | 200 MPa to 300 MPa |

| Hardness | Brinell Hardness Number(BHN): 120-180 |

| Elongation | ~40%(good ductility) |

| Thermal Conductivity | Moderate, lower than pure copper |

| Electrical Conductivity | 15-25% IACS (lower than pure copper due to nickel content) |

| Magnetic Properties | Non-magnetic or weakly magnetic |

| Machinability | Good, though harder than pure copper |

| Weldability | Weldable using methods like TIG and MIG welding |

| Corrosion Resistance | Excellent in seawater and harsh chemical environments |

| Common Applications | -Marine (heat exchangersmarine hardwarecondensers |

| -Chemical and Petrochemical (pumpsvalvespiping systems) | |

| -Electronics (electrical contactscomponents in corrosive environments) | |

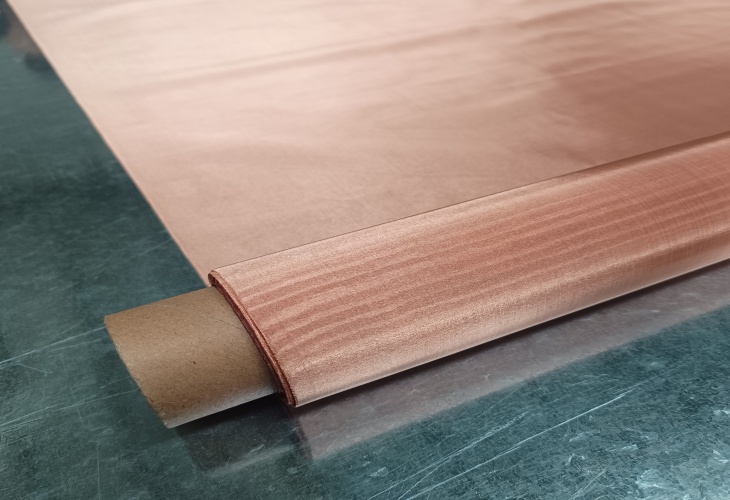

| -Industrial (thermal management,alloy mesh for filtration and sieving) |