| Chemical Composition(%) | |||||||||

| Ni | Mo | Fe | C | Co | Cr | Mn | Si | P | S |

| Balance | 26-30 | 0-2 | 0-0.02 | 0-1 | 0-1 | 0-1 | 0-0.1 | 0-0.04 | 0-0.03 |

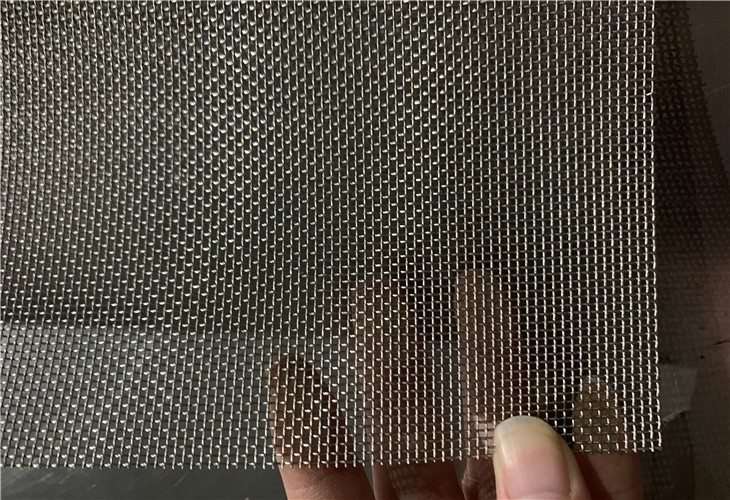

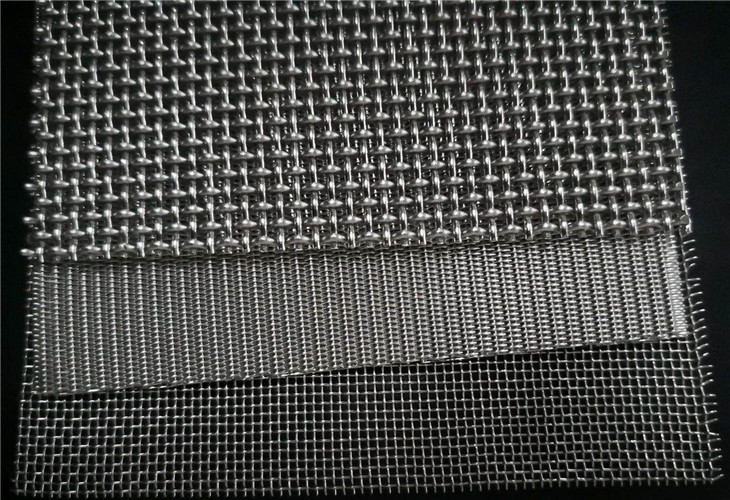

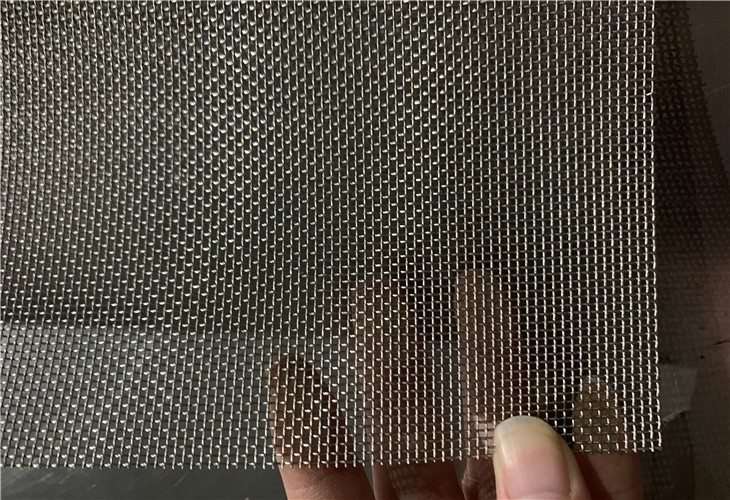

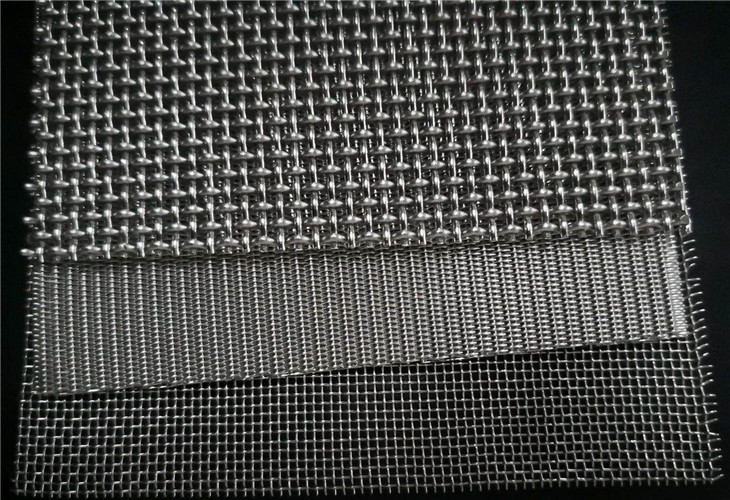

- Weaving type:plain,twill,dutch,crimped.

- Mesh count:1 to 300 mesh. 100*760 mesh

Alloy Metal Mesh

Hastelloy B2 is a solid solution strengthened, nickel-molybdenum alloy, with significant resistance to reducing environments like hydrogen chloride gas, and sulfuric, acetic and phosphoric acids. Molybdenum is the primary alloying element which provides significant corrosion resistance to reducing environments. This nickel steel alloy can be used in the as-welded condition because it resists the formation of grain-boundary carbide precipitates in the weld heat-affected zone.

This nickel alloy provides excellent resistance to hydrochloric acid at all concentrations and temperatures. In additions, Hastelloy B2 has excellent resistance to pitting, stress corrosion cracking and to knife-line and heat-affected zone attack. Alloy B2 provides resistance to pure sulfuric acid and a number of non-oxidizing acids.

| Chemical Composition(%) | |||||||||

| Ni | Mo | Fe | C | Co | Cr | Mn | Si | P | S |

| Balance | 26-30 | 0-2 | 0-0.02 | 0-1 | 0-1 | 0-1 | 0-0.1 | 0-0.04 | 0-0.03 |

Some characteristics of Hastelloy B-1 wire cloth which dictate its use are:

Hastelloy B-2 wire cloth is principally used in extremely corrosive reducing and oxidizing settings. As such, Alloy B-2 is widely used in the most severe chemical processing, pollution control, and pulp & paper applications. Additional industries and applications which commonly use Alloy B-2 wire cloth include: