| Chemical Composition(%) | |||

| Cu | Pb | Fe | Zn |

| 63-68.5 | 0-0.09 | 0-0.07 | Balance |

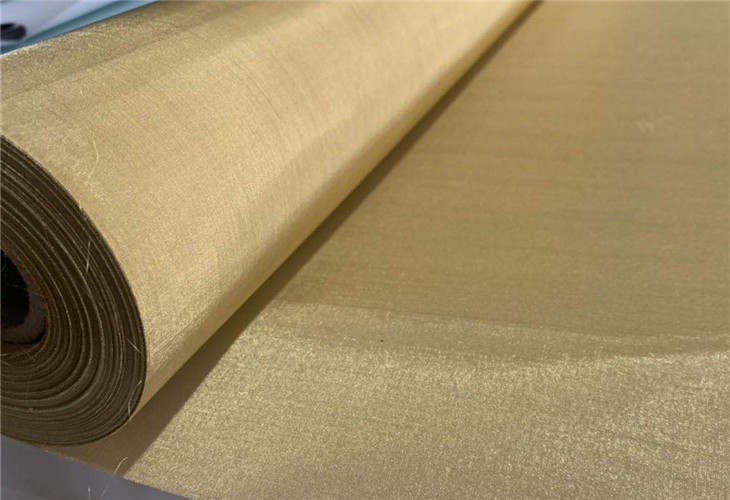

- Weaving type:plain,twill

- Mesh count:1 to 200 mesh

- Stock Size:

Mesh Size Wire Diameter 20mesh 0.15mm 20mesh 0.2mm 20mesh 0.19mm 30mesh 0.23mm 40mesh 0.19mm 40mesh 0.2mm 50mesh 0.12mm 60mesh 0.12mm 100mesh 0.1mm 110mesh 0.1mm 200mesh 0.05mm 220mesh 0.05mm 16x110mesh 0.4×0.28mm