| Chemical Composition(%) | |||

| Cu | Pb | Fe | Zn |

| 89-91 | 0-0.05 | 0-0.05 | Balance |

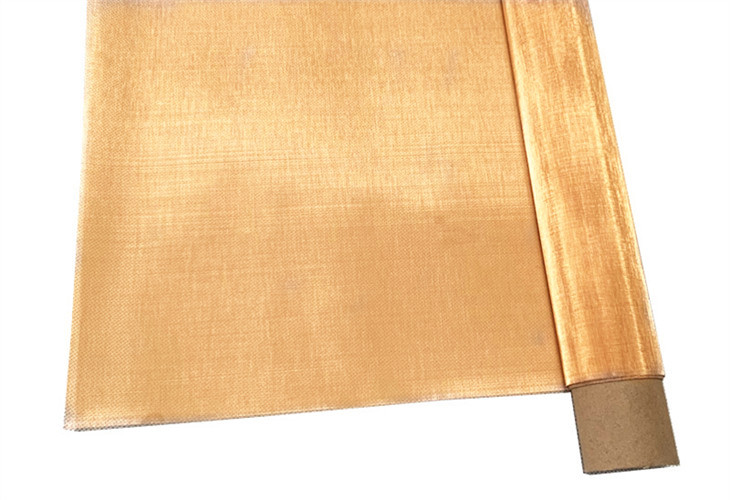

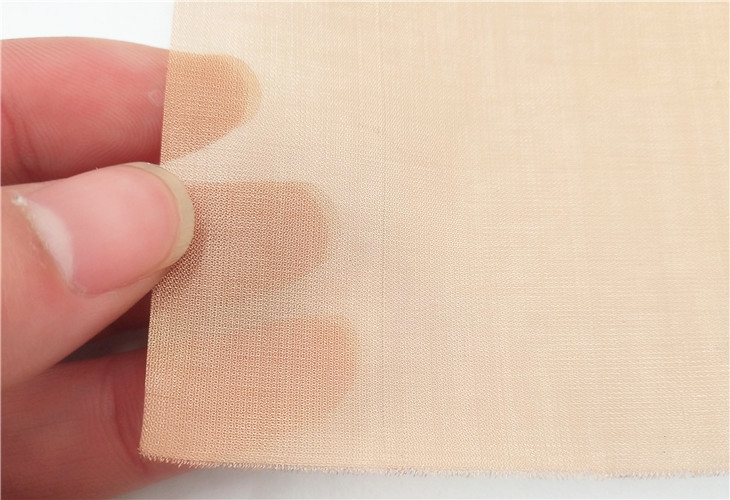

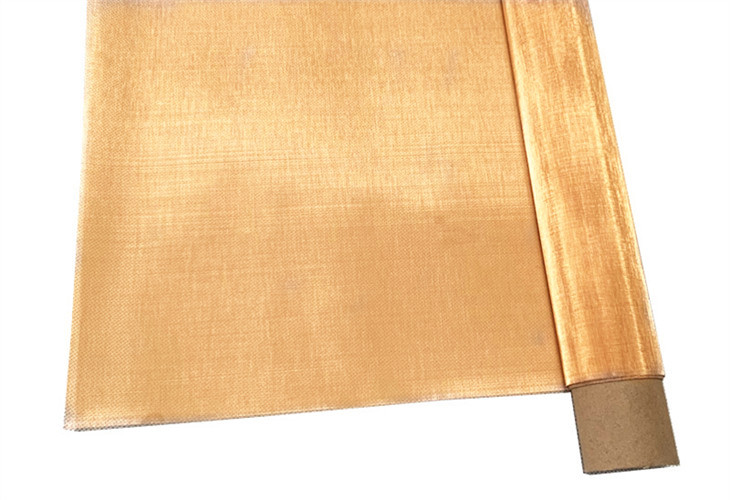

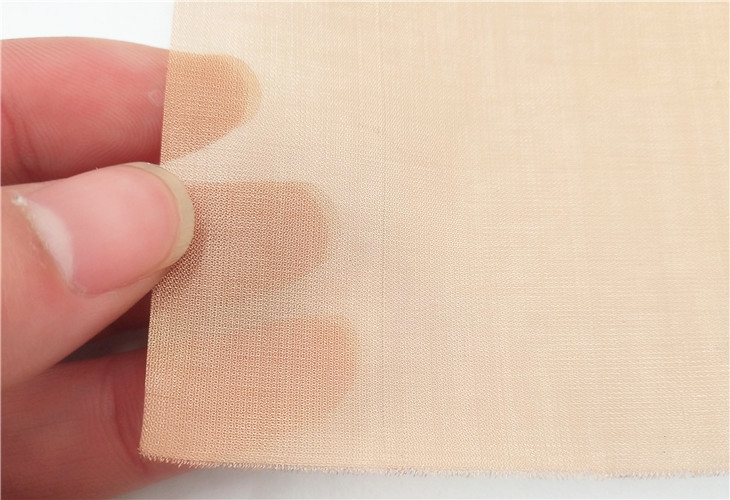

- Weaving type:plain,twill

- Mesh count:1 to 500 mesh

- Stock Size:

Mesh Size Wire Diameter 60mesh 0.15mm 80mesh 0.12mm 40/30mesh 0.27/0.3mm 150mesh 0.06mm 200mesh 0.05mm 300mesh 0.04mm

Copper Series Mesh

Bronze wire mesh (aka C220 bronze wire mesh) is the most extensively used bronze alloy in the industrial wire cloth world. As its common industry name suggests, 90-10 commercial bronze is comprised of 90% copper and 10% zinc, with small additions of lead (0.025%) and iron (0.025%). When compared to copper wire cloth, C220 bonze wire cloth possesses much better abrasion resistance, hardness, and tensile strength; it also exhibits improved corrosion resistance and lower electrical conductivity. As a higher zinc content results in a stronger, more ductile material, 90-10 commercial bronze is weaker and less ductile than other brass wire cloth alloys (H65 brass). In comparison to phosphor bronzes, C220 bronze is a softer material.

| Chemical Composition(%) | |||

| Cu | Pb | Fe | Zn |

| 89-91 | 0-0.05 | 0-0.05 | Balance |

| Mesh Size | Wire Diameter |

| 60mesh | 0.15mm |

| 80mesh | 0.12mm |

| 40/30mesh | 0.27/0.3mm |

| 150mesh | 0.06mm |

| 200mesh | 0.05mm |

| 300mesh | 0.04mm |

Some characteristics of 90-10 commercial bronze wire cloth which dictate its wide use are:

90-10 commercial bronze wire cloth is principally used in liquid filtration and particle separation, insect screen, and architectural applications. Additional industries and applications which commonly use C220 bronze wire cloth include: