| Chemical Composition(%) | |

| Cu | Other |

| 99.9 | 0-0.1 |

- Weaving type:plain,twill

- Mesh count:1 to 400 mesh

Copper Series Mesh

CDA 110 tinned copper wire mesh (aka C11000 tinned copper wire mesh) is an infrequently used copper alloy in the world of wire cloth. C11000 copper itself is a pure, electrolytic tough pitch copper with a minimum copper content of 99.9%. As with other pure coppers alloys, CDA 110 copper possesses excellent electrical and thermal conductivity, and is very malleable, pliable, and ductile.

The process of tinning C11000 copper involves taking CDA 110 copper wire and thinly coating the wire with a layer of tin (known as tinplate). The tinplate offers an additional layer of protection for the wire against corrosion (i.e. humidity, heat, wet environments, etc.), while allowing the wire to maintain the same level of electrical conductivity. While tinned copper wire mesh costs more than pure copper wire mesh, it can withstand corrosion up to 10 times longer.

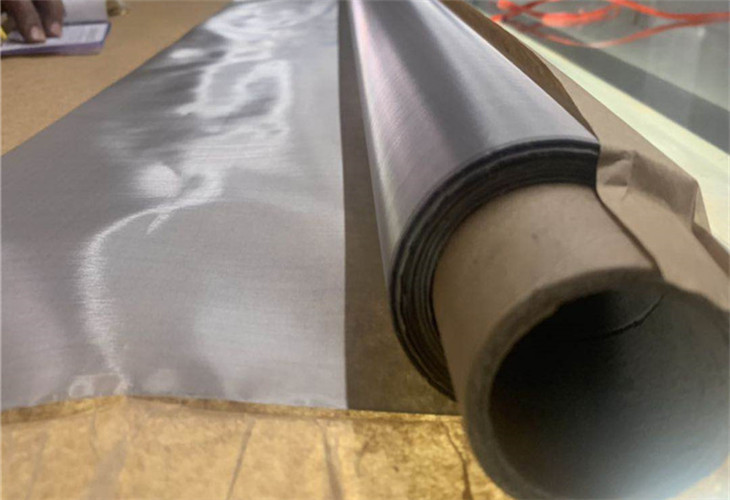

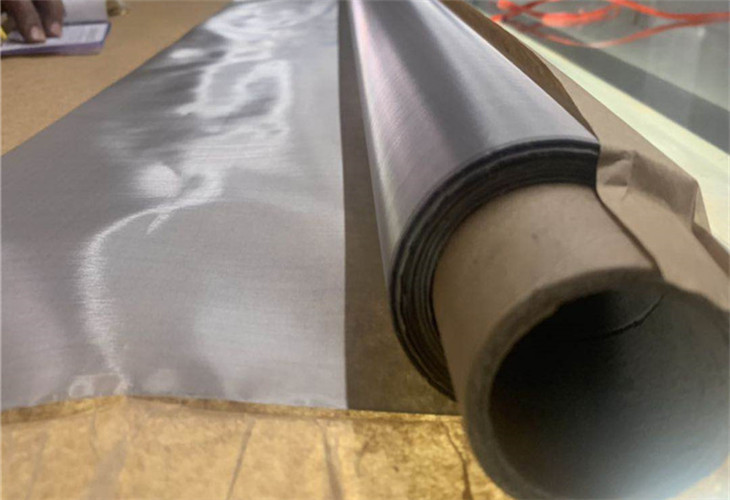

Thanks to the tinplate, C11000 tinned copper wire cloth is silvery-white in color following weaving. The tinplate helps prevent the surface from patina; thus, over time, the surface does not turn a greenish/blue color (known as verdigris) as happens with pure CDA 110 copper wire mesh.

| Chemical Composition(%) | |

| Cu | Other |

| 99.9 | 0-0.1 |

Some characteristics of CDA 110 tinned copper wire cloth which dictate its use are:

As the tinplate layer prevents corrosion, CDA 110 tinned copper wire cloth is principally used in settings where improved resistance to humidity, high temperatures, and wet environments is required than can be provided by pure copper. Some of these applications include Faraday cages, RFI shielding, HVAC units, and other electrical applications. Additional industries and applications which use C11000 tinned copper wire cloth include: