- Materrial of perforated mesh(Punched metal sheet mesh):

–Stainless steel 304 316 316L 904L 430 321 2205..

–Titanium, Nickel, Tungsten, Molybdenum,

–Monel, hastelloy, inconel, and other Alloy metals.

–GI, Mid steel grade, Aluminum.

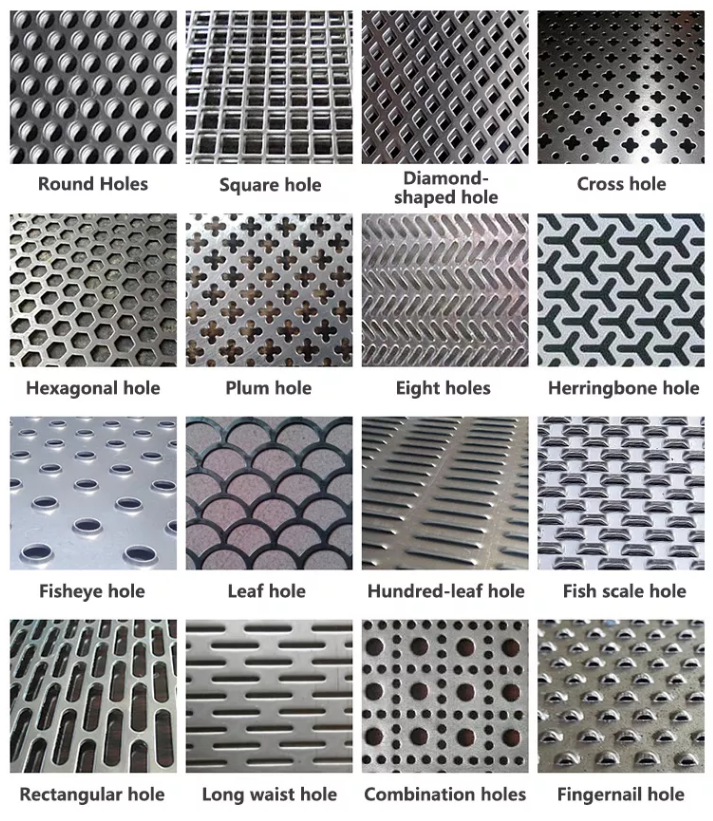

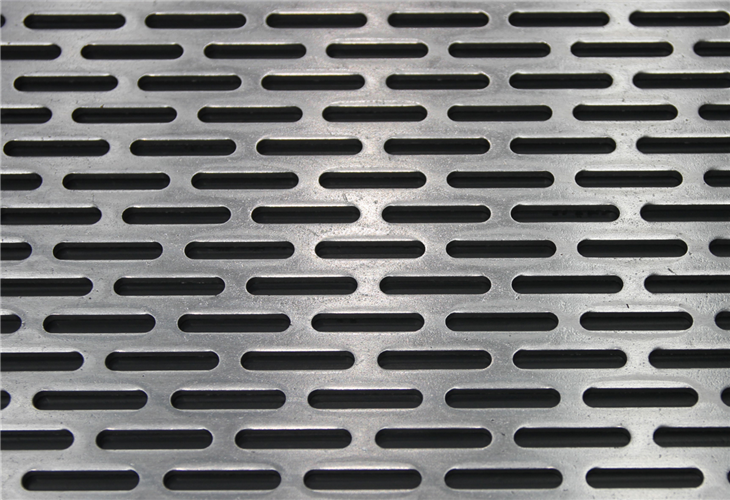

- Hole shape: round, square, diamond, cross, hexagon, plum, eight, herringbone, fisheye, leaf, hundred-leaf, fis-scale, long-waist, rectangle and others.

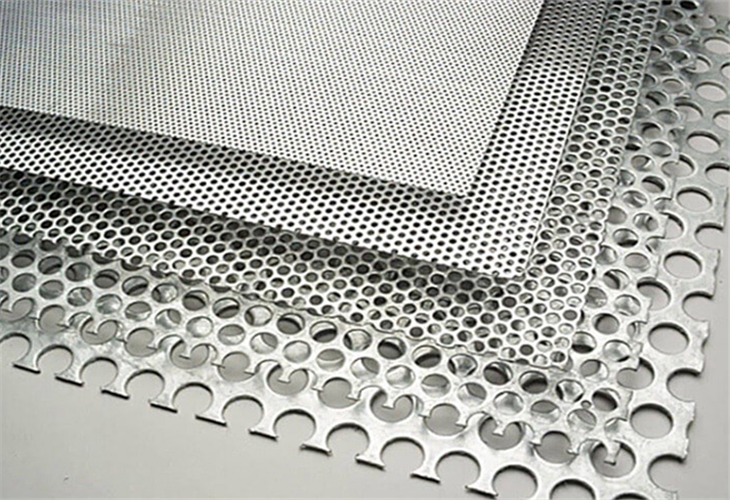

- Thickness: 0.2mm-15mm

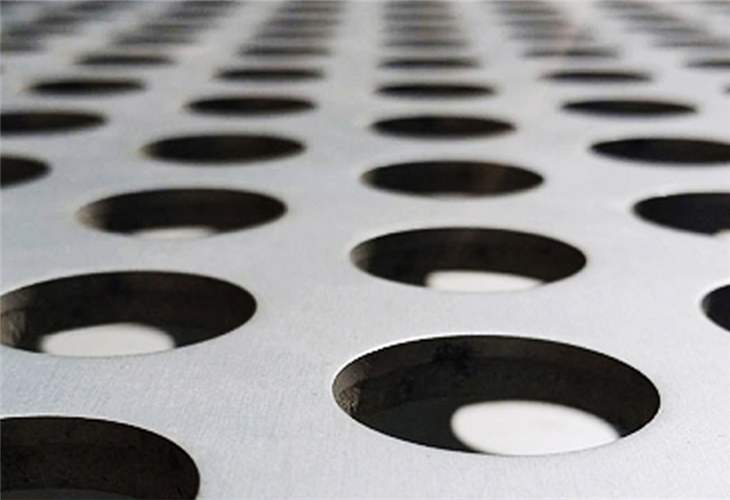

- Hole size: 0.2-30mm

- Sheet size:

–1000mmx2000mm

–1220mmx2400mm

–1250mmx2500mm

–1500mmx3000mm

–1500mmx6000mm

- Packing: in rolls or flat panel.

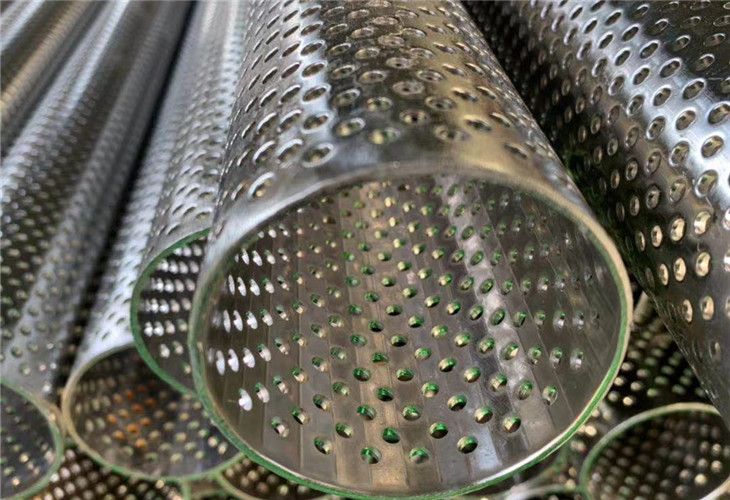

- Shapes: perforated metal sheet can be shaped into perforated cylinder tubes for filtering or support structure of the filter cartridges.

Noted: any other sizes of the perfoarted sheet can be made as per your request. Please ocntact us directly for the details!