| Chemical Composition(%) | ||||||

| C | Mn | S | Si | Fe | Cu | Ni |

| 0-0.3 | 0-2 | 0-0.024 | 0-0.5 | 0-2.5 | 28-34 | Balance |

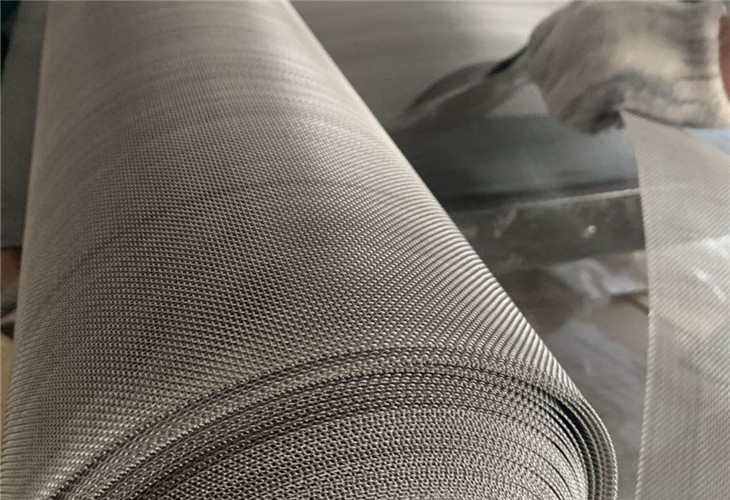

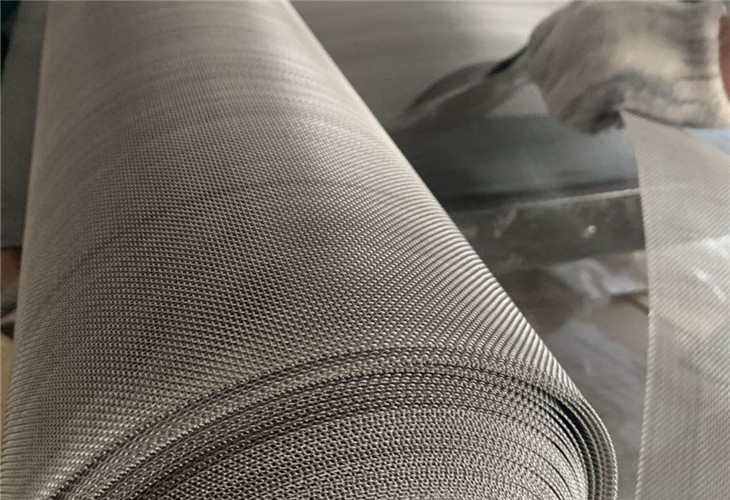

- Weaving type:plain,twill,dutch,crimped.

- Mesh count:1 to 350 mesh. 200*1800 mesh

Nickel Alloy Metal Mesh

Monel 400 wire mesh (Alloy 400) is a nickel-copper alloy that demonstrates good resistance in a wide variety of corrosive environments. Its nominal composition of ~67% nickel and ~31% copper traces its roots back to the early 1900’s when it was first developed by the International Nickel Company in an effort to use the high-copper-content nickel ore found in its Ontario, Canada mines. Alloy 400 wire cloth has excellent durability and strength following weaving, making it well suited for use in many industrial and commercial applications. In comparison to copper alloys, Monel 400 wire cloth is more resistant to oxidizing conditions. Versus Nickel 200, Alloy 400 wire mesh has greater resistance in reducing environments. As its color and appearance nearly match that of stainless steal, given Monel 400’s higher price point, it is not an alloy of choice for decorative applications.

| Chemical Composition(%) | ||||||

| C | Mn | S | Si | Fe | Cu | Ni |

| 0-0.3 | 0-2 | 0-0.024 | 0-0.5 | 0-2.5 | 28-34 | Balance |

Some characteristics of Monel 400 wire cloth which dictate its wide use are:

Monel 400 wire cloth is principally used in aerospace, chemical, brackish water, seawater, and power generation applications given its superior corrosion resistance properties. Additional industries and applications which commonly use Alloy 400 wire cloth include: