| Chemical Composition(%) | |||||||||

| Ni | Cr | Mo | Fe | W | C | Si | Co | Mn | V |

| 65-66 | 1-3 | 27-32 | 1-3 | 0-3 | 0-0.01 | 0-0.1 | 0-3 | 0-3 | 0-0.2 |

| P | S | Ti | Cu | Al | Zr | Nb/Cb | Ta | Ni+Mo |

| 0-0.03 | 0-0.01 | 0-0.2 | 0-0.2 | 0-0.5 | 0-0.1 | 0-0.2 | 0-0.2 | 94-98 |

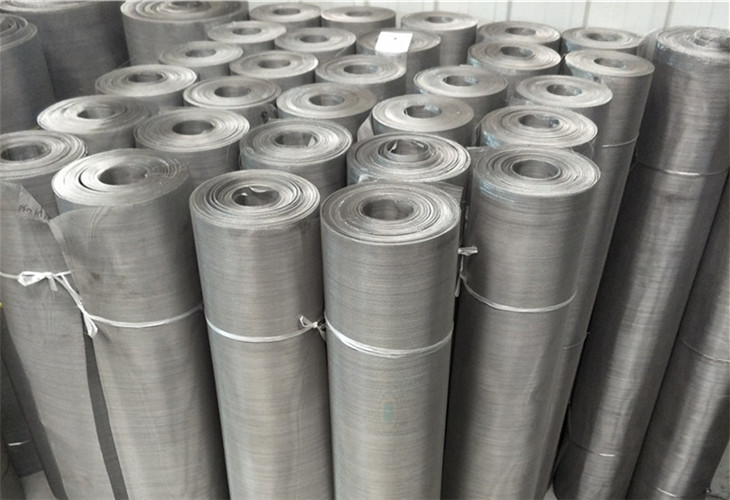

- Weaving type:plain,twill,dutch,crimped.

- Mesh count:1 to 300 mesh. 100*760 mesh