| Chemical Composition(%) | ||||||||||||

| C | Mn | P | S | Si | Cr | Ni | Mo | Ti | Fe | Co | Nb+Ta | Al |

| 0-0.1 | 0-0.5 | 0-0.015 | 0-0.015 | 0-0.5 | 20-23 | Balance | 8-10 | 0-0.4 | 0-5 | 0-1 | 3.15-4.15 | 0-0.4 |

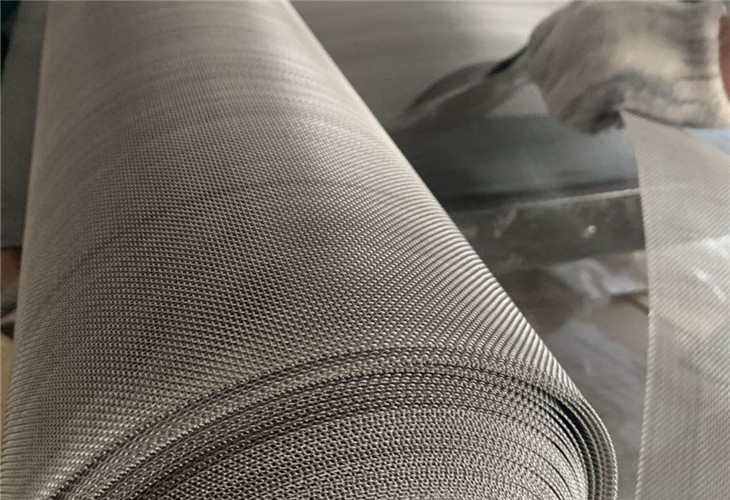

- Weaving type:plain,twill,crimped.

- Mesh count:1 to 200 mesh.

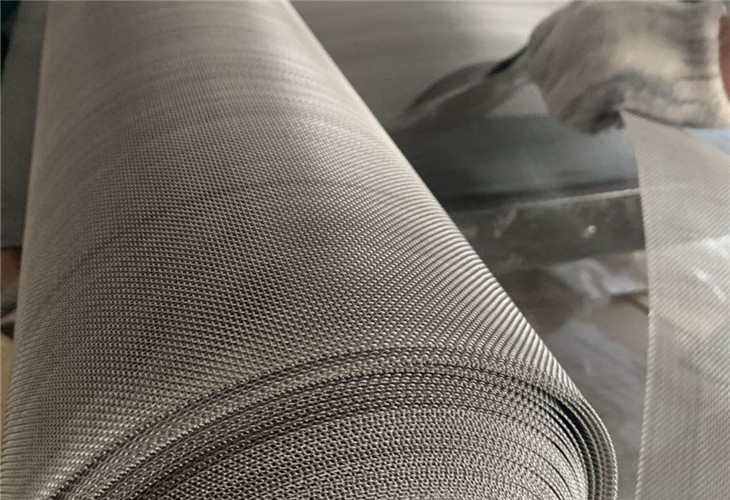

Nickel Alloy Metal Mesh

Inconel 625 wire mesh (Alloy 625) is a nickel-chromium-molybdenum-niobium alloy designed for applications requiring resistance to both corrosion and extreme temperatures. Due to the solid-solution effects of the molybdenum (~9%) and niobium ([+tantalum] ~3.65%) in the nickel-chromium matrix, Alloy 625 demonstrates superior mechanical performance in extreme temperatures as compared to Alloy 600. As such, Inconel 625 wire cloth maintains outstanding strength and toughness in environments with temperatures from cryogenic to 1800°F. Its high nickel (~61%) content gives Alloy 625 wire cloth excellent resistance to pitting and crevice corrosion, chloride stress-corrosion cracking, and a wide array of inorganic and organic compounds. When compared to pure Nickel 200 and Nickel 201, the high chromium (~21.5%) content of Inconel 625 wire mesh gives it superior resistance in oxidizing settings.

| Chemical Composition(%) | ||||||||||||

| C | Mn | P | S | Si | Cr | Ni | Mo | Ti | Fe | Co | Nb+Ta | Al |

| 0-0.1 | 0-0.5 | 0-0.015 | 0-0.015 | 0-0.5 | 20-23 | Balance | 8-10 | 0-0.4 | 0-5 | 0-1 | 3.15-4.15 | 0-0.4 |

Some characteristics of Alloy 625 wire cloth which dictate its use are:

Inconel 625 wire cloth is principally used in high-temperature environments that require superior, long-term strength and toughness. As such, Alloy 625 is widely used in chemical processing, aerospace, and nuclear steam generator equipment. Additional industries and applications which commonly use Alloy 625 wire cloth include: