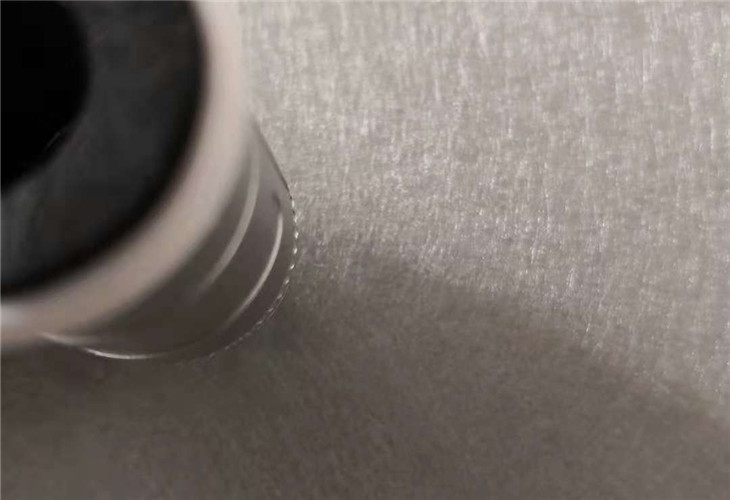

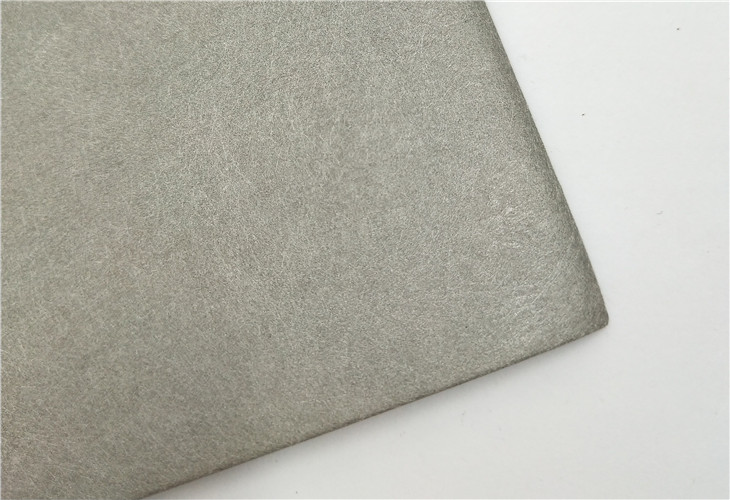

- Material: 304, 304L,316, 316L, 310s stainless steel etc.

- Micron: 3-100um

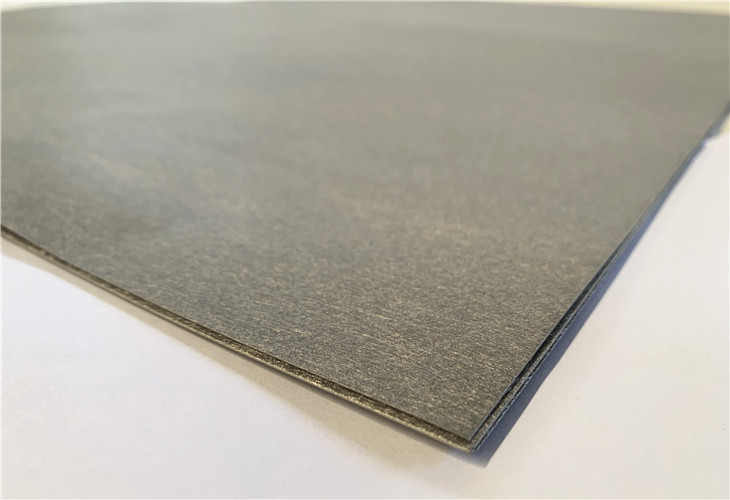

- Thickness: 0.25mm-1.2mm

- Micron size: 10um 5um 20um 40um 50um…

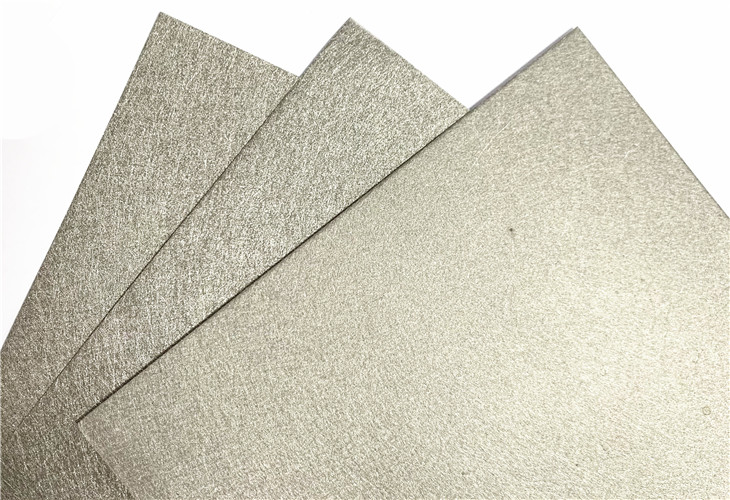

- Sheet Size: 1000x1000mm 1200x1000mm 1000x1500mm…

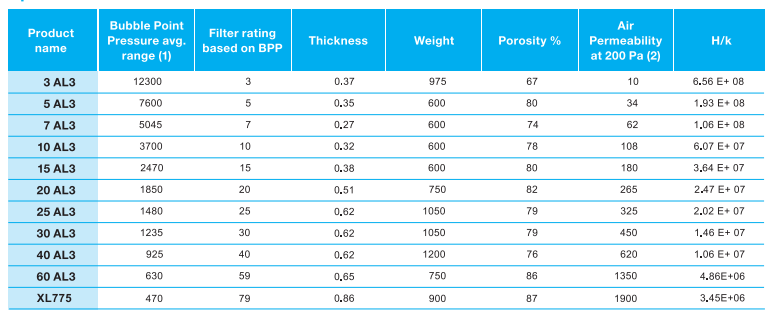

- Data sheet of the stainless steel felts:

- Stock sizes of the stainless steel fiber felts in Aegis [any other sizes can be produced]

| Thickness | Micron Size | Sheet size |

| 0.25mm | 3um/5um/10um | 450x1220mm\450x510mm\105x705mm |

| 0.35mm | 5um/10um | 435x745mm |

| 0.52mm | 5um/20um | 700x1000mm 300x490mm |

| 0.42mm | 20um/4oum | 300x490mm\700x1000mm |

| 0.4mm | 40um | 210x240mm |

| 1.1mm | 20um/15um/25um/100um /40um/60um | 100x150mm\150x150mm/500x1180mm\180x200mm |

| 0.67mm | 60um/50um/40um | 275x1050mm\950x1180mm\100x100mm\100x200mm |

| 1.5mm | 5um/6oum | 100x100mm\100x200mm\1180x1540mm |