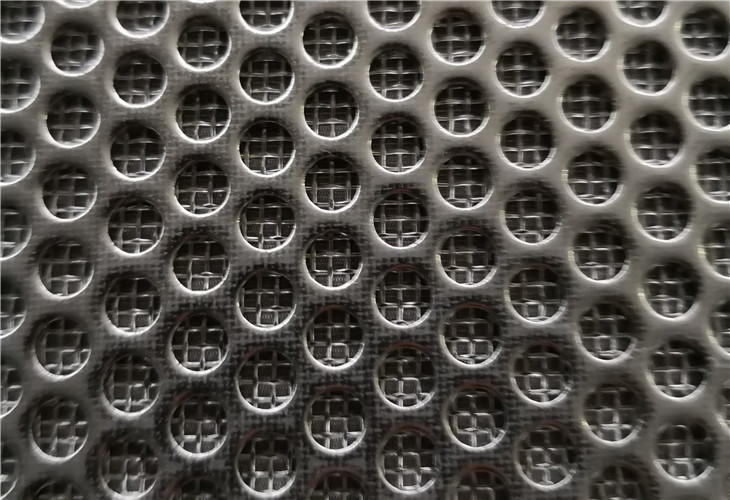

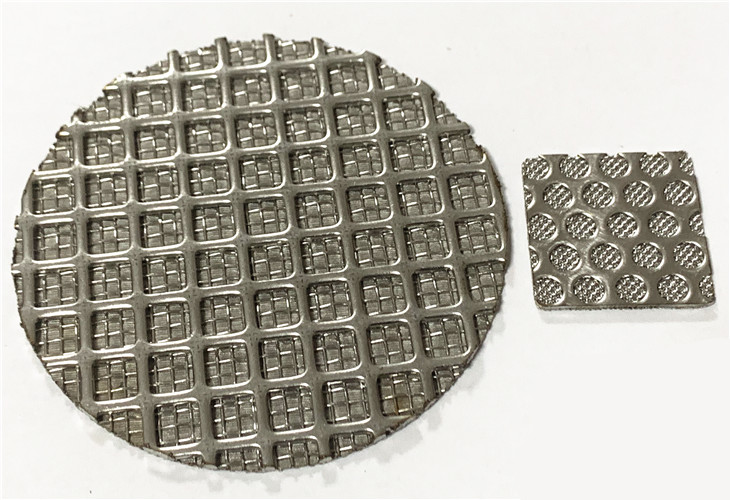

- Material: 304, 304L, 316, 316L, 904L, 2205, 2507, hastelloy, monel, inconel etc.

- Micron: 1-200um

- Layers: 2-10 layers

- Size: 500x1000mm, 600x1000mm, 600x1200mm, 1000x1000mm, 1200x1200mm etc.

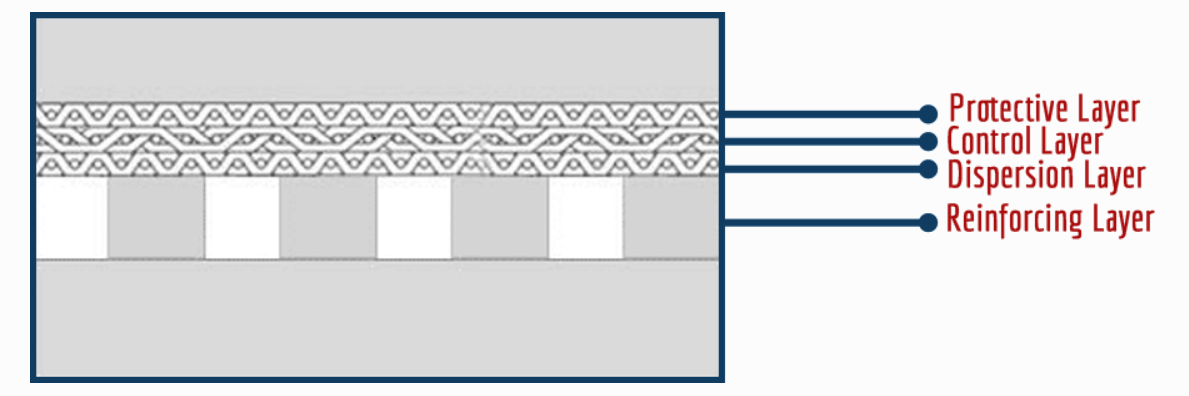

Model Filter rating Structure Thickness Weight Porosity AGS-1.5T 2-100um 60 mesh+filter layer+30 mesh+∮1.5x3px1.0T 1.5mm 8.2kg/m2 30% AGS-2.0T 2-200um 30 mesh+filter layer+30 mesh+∮4x5px1.0T 2.0mm 6.7kg/m2 57% AGS-2.5T 2-200um 30 mesh+filter layer+30 mesh+∮5x7px1.5T 2.5mm 9.8kg/m2 50% AGS-3.0T 2-200um 30 mesh+filter layer+60 mesh+∮6x8px2.0T 3.0mm 11.8kg/m2 50% AGS-4.0T 2-200um 20 mesh+filter layer+20 mesh+10 mesh+∮8x10px2.5T 4.0mm 14.2kg/m2 55% AGS-4.3T 5-200um 20 mesh+filter layer+20 mesh+10 mesh+∮10x13px3.0T 4.3mm 16.9kg/m2 50%